Release time:2024-06-26

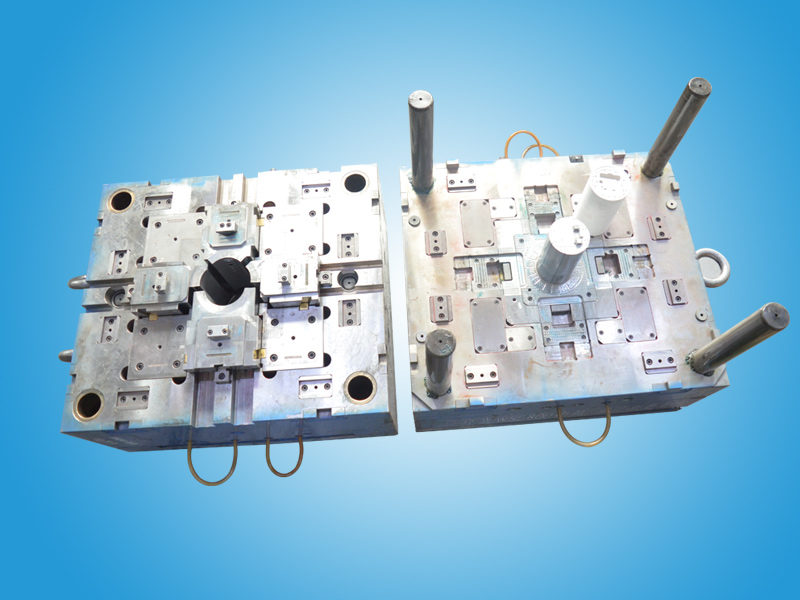

Plastic injection moldingMold processingThe accuracy of plastic parts determines the accuracy, so it is very important to control the accuracy of injection mold processing. So how should we control the accuracy in the process of mold processing?

1. Optimize the processing technology of plastic injection mold

Different processing methods should be selected for different die structures. When controlling the precision of mold processing, we should meet the actual work requirements, select the appropriate mold processing technology and strictly implement it. Various plastic injection molds have different requirements for performance. In actual production, we should make full use of the characteristics of various processes and choose the appropriate process type of mold processing from various processes. Each processing method has its own characteristics, and the use of different processing methods will also affect the machining accuracy of the mold.

2. Determine appropriate processing equipment

All kinds of equipment used in mold processing have a certain impact on the processing process and the use of equipment. There are many kinds of equipment used in the processing process, and their functions are also different. In order to improve the accuracy of plastic injection mold processing, we must ensure that the processing equipment used meets the standards, correctly select the appropriate equipment, better control the processing links of each equipment, and ensure the accurate completion of each work. The key to mold processing quality is to choose reasonable processing equipment.

3. Form an appropriate control system

Plastic injection mold processing has a certain process flow, and will be made into different shapes according to different needs. In the process of processing, we should not only choose processing equipment, but also choose appropriate raw materials, and fully analyze the actual needs of plastic injection molds and the functions of molds.