Release time:2023-08-09

Injection moldingMold processingIt is a very refined activity, and each step determines the final quality of injection mold and injection products, so it is not an easy thing for injection mold processing. So what is the specific reason for the difficulty of injection mold processing?

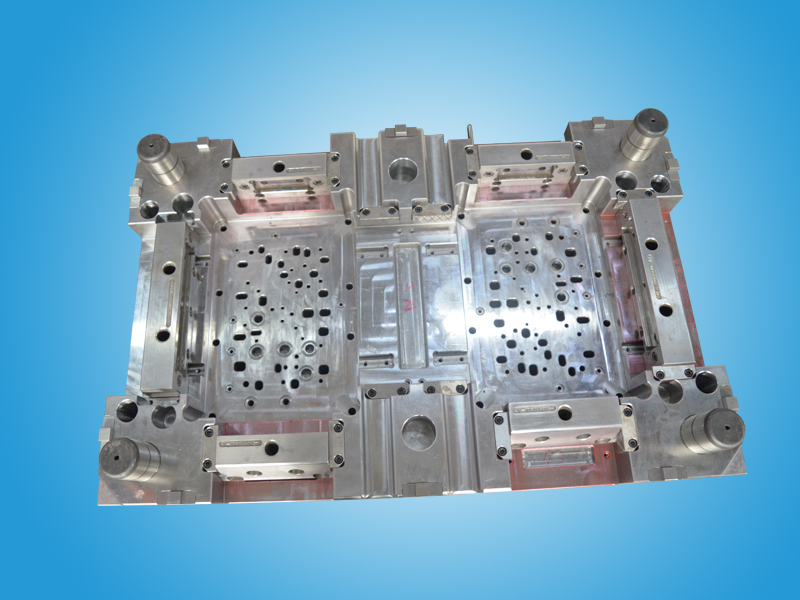

(1) The machining shape of cavity and core is complex

The complex shape of injection mold cavity and core will be difficult to process, especially the blind hole of the cavity or the molding surface of the cavity. If the traditional injection mold processing method is adopted, it not only requires workers to have a higher level of processing technology, more tooling and fixtures, but also requires a longer processing cycle.

(2) The precision, surface requirements and service life requirements of injection mold are relatively high

Because the precision, surface requirements and service life requirements of special products for injection mold processing are relatively strict, which greatly improves the difficulty of manufacturing injection mold processing and mold manufacturing cycle.

(3) The process of mold processing is long and the processing time is short

Due to the high requirements for the shape and dimensional accuracy of plastic products, and the different characteristics of plastic materials, after the injection mold is manufactured, it still needs to be tested and repaired repeatedly, which makes the development and delivery time very tight.

(4) Design and manufacture in different places

Generally, injection mold manufacturers design and manufacture molds according to the requirements of users, but the products produced by injection molding are in other injection molding plants. In this way, the design of plastic products, the design and manufacture of injection molds and the production of products are all carried out in different places.