With the development of the times, plastic shell has been more and more deeply into our life. Many friends can't avoid using pla…… MORE

With the continuous implementation of various epidemic prevention and control measures, although the total number of confirmed c…… MORE

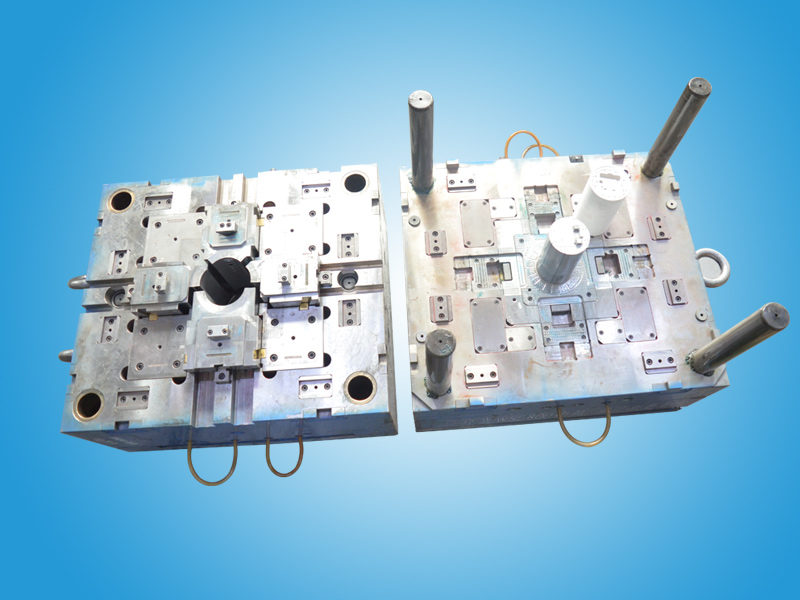

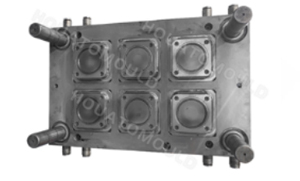

The key link of injection molding is to make various forms of plastic into products or blanks with required shapes. There are mo…… MORE

During the injection molding process, the dents of the plastic shell are shrinkage dents generated after the plastic is cooled a…… MORE

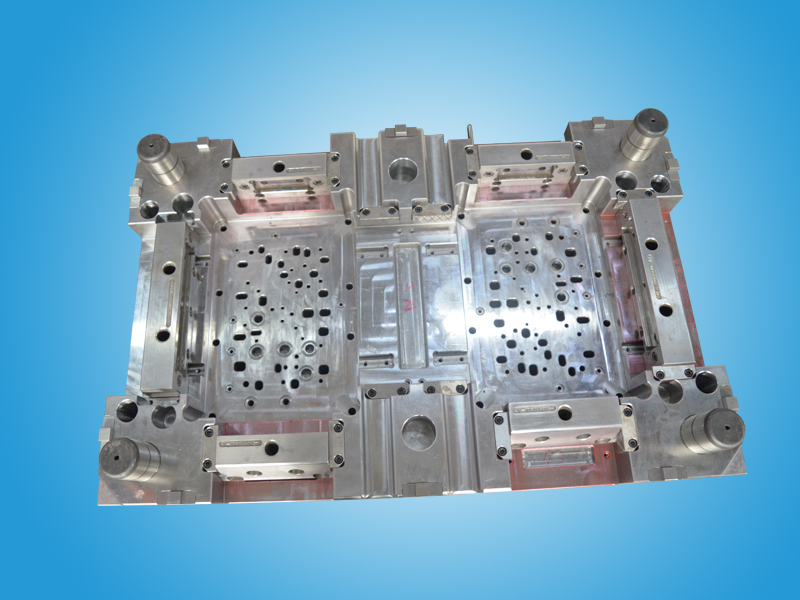

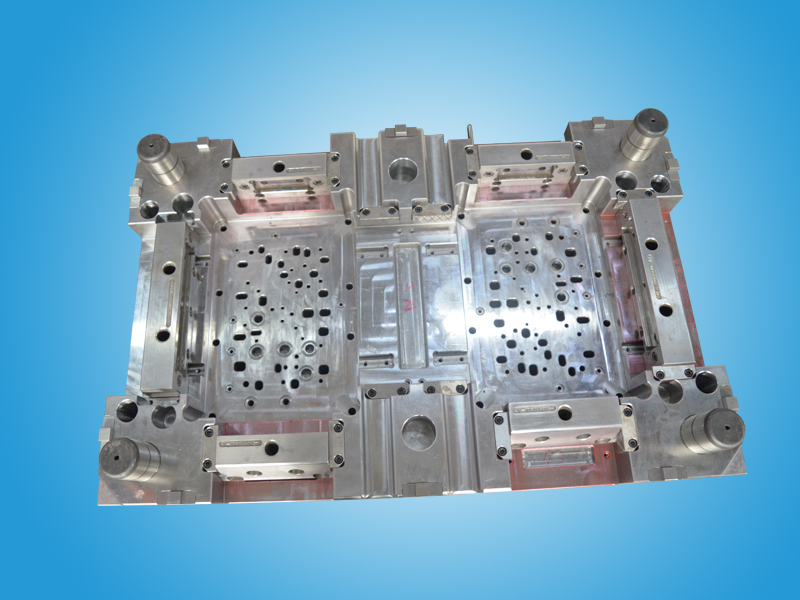

The finished product quality and processing cost of injection mold are closely related to the quality of injection mold. Therefo…… MORE

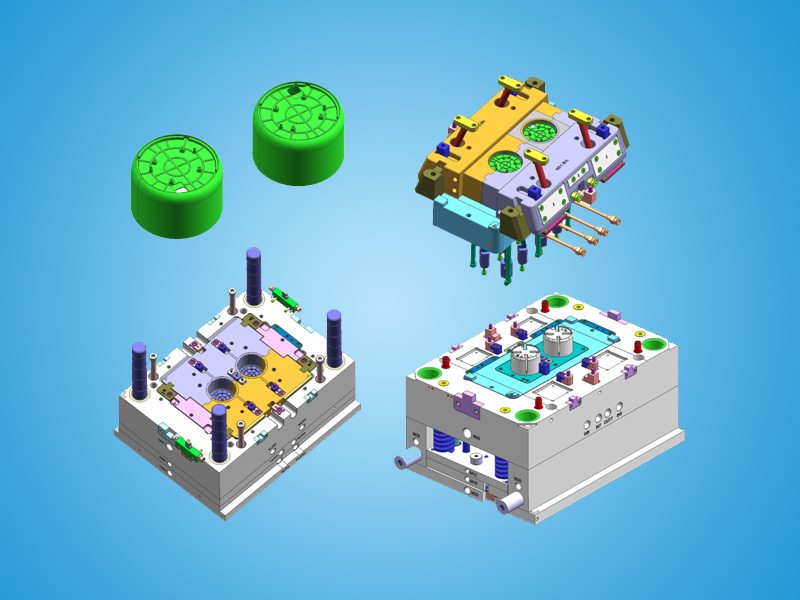

At present, some cooperative customers are making security camera shell products. Some customers say that the injection color is…… MORE

The shell of medical devices is usually manufactured by low-pressure pouring, which is produced by simple molds, such as aluminu…… MORE

There is still a lot of common sense to master about the processing skills of medical device shells. On this basis, it is possib…… MORE

As mold processing is facing the pace of keeping up with new design changes and minimizing costs, the demand for five axis machi…… MORE

There are many materials used in the manufacture and production of medical device shells, such as ABS, PP, PE, stainless steel a…… MORE

Omnidirectional injection molding is to inject the plastic melt into the middle of the closed mold cavity under high pressure, a…… MORE

What is the manufacturing process of insert molding? Insert molding is the process of forming thermoplastic materials around pre…… MORE