What should be considered when choosing a manufacturer for injection molding? Injection molding products are used in many fields…… MORE

療器材類/檢測(cè)儀外殼.jpg)

(1) Geometry and accuracy. The geometric dimension of the blister shell includes the dimension from the cutting surface to the f…… MORE

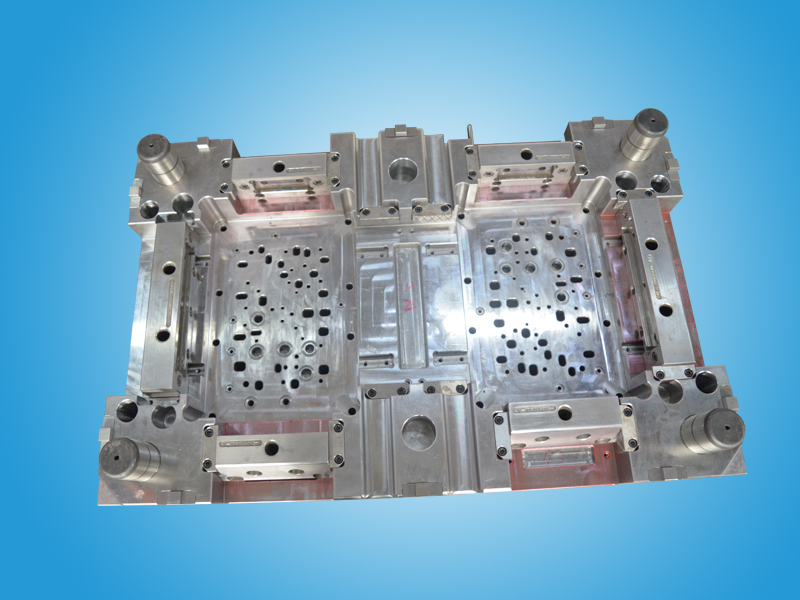

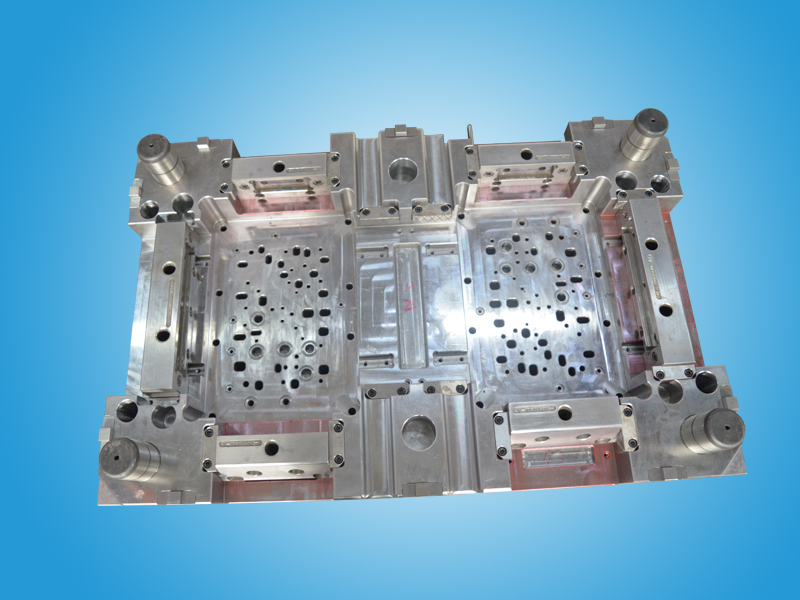

The accuracy of plastic injection mold processing determines the accuracy of plastic parts, so it is very important to control t…… MORE

Multi material injection molding is to integrate a variety of plastic materials with different characteristics to improve the ad…… MORE

1、 Light weight led waterproof power supply plastic shell is a relatively light material, with a relative density of 0.90~2.2. O…… MORE

At present, the proportion of plastic mold in the whole mold industry is about 30%, and the proportion in mold import and export…… MORE

療器材類/檢測(cè)儀外殼3.jpg)

In the process of processing medical device shells, the first thing to do is to blanking them. When good blanking is achieved, t…… MORE

1. Shrinkage in injection molding is a common problem in injection molding, especially for plastic products with high surface qu…… MORE

Our friends in the production line know that there are some operating rules for injection molding, and we should know that safet…… MORE

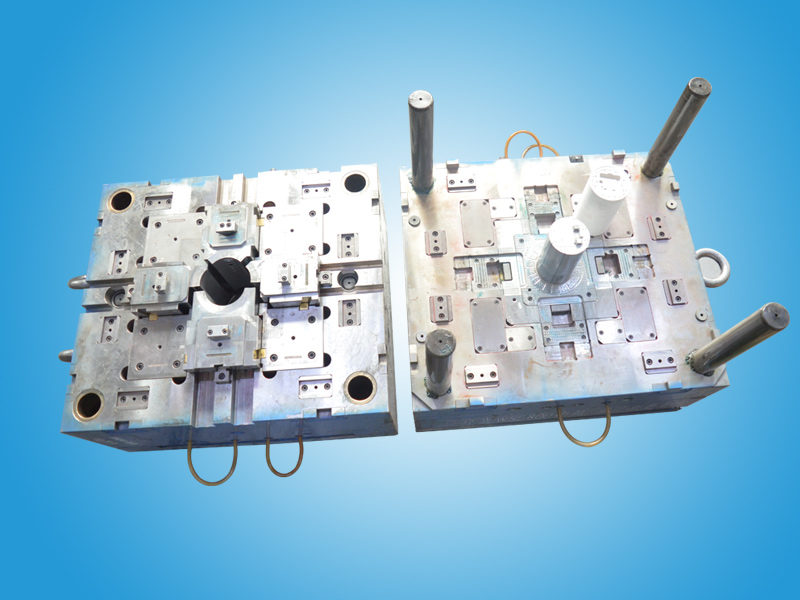

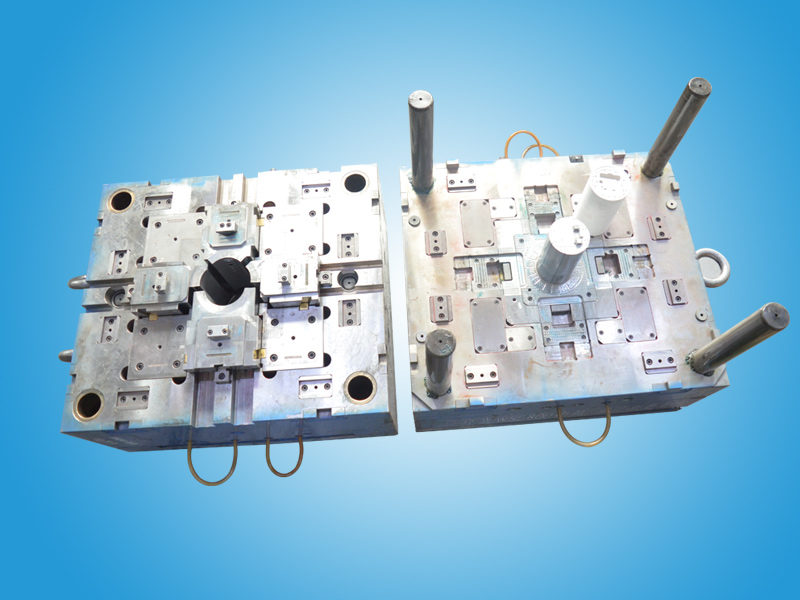

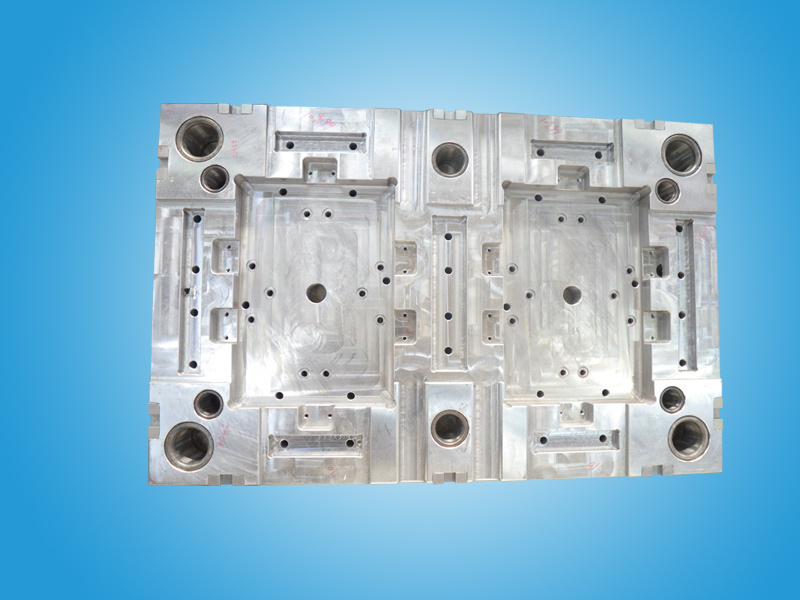

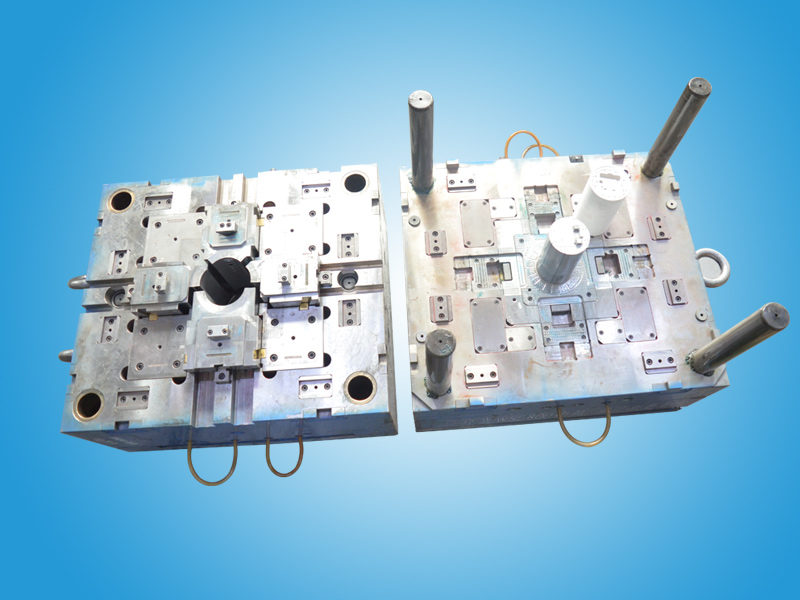

What are the structural design ideas of plastic shell mold? Nowadays, with the continuous improvement of people's aesthetic conc…… MORE

療器材類/美容儀器殼9.jpg)

Large medical devices are relatively expensive products, and their volume is also relatively large, so it is troublesome to main…… MORE

The manufacturer of the medical device shell selects the thick sheet Blister processing technology to improve the product perfor…… MORE